LAB TESTING AREAS

Asbestos Analysis

Discover peace of mind with our comprehensive asbestos testing service. As specialists in environmental safety, we prioritize your well-being by providing accurate and swift testing solutions. Our state-of-the-art laboratory is equipped with cutting-edge technology, ensuring precise analysis of samples to detect even the slightest trace of asbestos.

With a team of experienced professionals dedicated to maintaining the highest industry standards, we deliver results you can trust. Whether you are a homeowner, contractor, or property manager, our seamless testing process is tailored to meet your specific needs. Safeguard your environment and make informed decisions with RJ Lee Group —your trusted partner in asbestos testing excellence.

Laboratory Testing for Asbestos

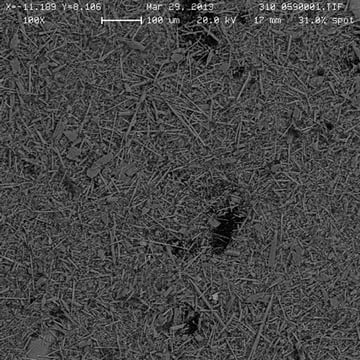

RJ Lee Group can test for asbestos in building materials, raw materials, air, water, and dust samples using three different analytical techniques: Polarized Light Microscopy (PLM), Phase Contrast Microscopy (PCM), and Transmission Electron Microscopy (TEM).

A History of Expertise and Innovation

RJ Lee Group has assessed environmental issues since the early 1980s when our Energy Technology Consultants (ETC) pioneered the recognition of specific air quality patterns. We developed a cutting-edge technique for identifying, measuring, and characterizing particles in the air using computer-controlled scanning electron microscopy (CCSEM).

RJ Lee Group has worked with clients in various industries, including the U.S. Environmental Protection Agency (EPA), to assess and provide solutions for environmental factors that could affect our health. Our services have grown over the years, from setting controls for unbound nanoparticles (UNP) to designing and building test chambers to simulate specific environmental conditions.

Today we offer our expertise for our clients’ environmental and compliance concerns and perform rigorous assessment and management of potential environmental risks.

Discuss Asbestos Testing with an Expert

Working with a testing lab with specialized knowledge and experience in Asbestos testing and remediation is essential to maintaining regulatory compliance and meeting environmental health and safety standards in the workplace. If you think asbestos may be a concern for your organization schedule time to discuss your concerns with one of our asbestos experts.