A History of Expertise and Innovation

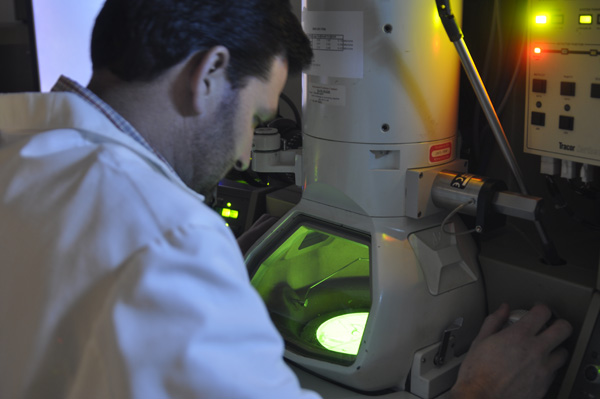

RJ Lee Group has assessed environmental issues since the early 1980s when our Energy Technology Consultants (ETC) pioneered the recognition of specific air quality patterns. We developed a cutting-edge technique for identifying, measuring, and characterizing particles in the air using computer-controlled scanning electron microscopy (CCSEM).

RJ Lee Group has worked with clients in various industries, including the U.S. Environmental Protection Agency (EPA), to assess and provide solutions for environmental factors that could affect our health. Our services have grown over the years, from setting controls for unbound nanoparticles (UNP) to designing and building test chambers to simulate specific environmental conditions.

Today we offer our expertise for our clients’ environmental and compliance concerns and perform rigorous assessment and management of potential environmental risks.

CONSULTING AREAS

Industrial Hygiene

RJ Lee Group offers comprehensive industrial hygiene services focusing on identifying, evaluating, analyzing, and controlling environmental elements in workplaces. Their expertise in analytical and consultative services spans materials research, environmental health, safety, and quality control. With a strong emphasis on industrial forensics, they proactively address potential risks to workers and the environment.

Particulate Matter Analysis

RJ Lee Group specializes in the identification of particulate composition to trace sources of contamination in various environments such as pharmaceuticals, electronics, construction, and coal mines. Their approach includes monitoring, sampling, and analyzing particulate matter, ensuring workplace safety and compliance with regulations.

Post-Disaster Assessments

The team at RJ Lee Group excels in post-disaster assessment and remediation. Their comprehensive services include site inspection, impact determination, and development of sampling plans. They work in collaboration with local, state, and federal agencies to manage and mitigate risks effectively.

Monitoring and Sampling Services

RJ Lee Group's monitoring and sampling services are extensive, covering aspects like Indoor Air Quality (IAQ), compliance with EPA requirements, and worker exposure assessment. They specialize in environmental monitoring, source identification, nuisance dust monitoring, and use of simulation chambers to replicate real-world conditions. Their team is equipped with the latest technologies to ensure accurate and reliable results.

Field Surveys, Evaluations, and Sampling

The field services team at RJ Lee Group is well-versed in on-site services and laboratory methodologies. They adhere to NIOSH, OSHA, EPA, and ASTM methodologies, employing the latest sampling techniques and field instrument technologies to provide thorough and accurate environmental evaluations.

Unbound Nanoparticles (UNP) Research

RJ Lee Group's investigation into man-made and natural Unbound Nanoparticles (UNPs), such as those found in diesel fumes, welding fumes, and coal combustion, is groundbreaking. They utilize advanced techniques like electron microscopy and spectroscopy for nanoscale studies and collaborate with various sectors for comprehensive nanoparticle characterization.

Expert Spotlight

Keith Rickabaugh

Technical Director, Materials & Analytical Services

Keith possesses over 25 years of involvement using applied sciences and instrumental analysis methods to investigate matters that have or may have legal relevance. One of his core competencies is the ability to simplify complex issues and clearly communicate findings to target audiences as well as to the general population.

Case study

How AeroTech Secured Its Future

When AeroTech Industries faced recurring defects in a crucial aircraft component, they were at risk of losing multi-million dollar contracts and jeopardizing the jobs of hundreds of employees. They enlisted the help of RJ Lee Group, who quickly deployed a team of technical experts. Through state-of-the-art forensic analysis, RJ Lee Group identified and rectified the root cause—a flaw in the casting process—eliminating the defect and preserving AeroTech's contracts.

Discuss Your Industrial Consultant Needs with RJ Lee Group

Embrace operational excellence and elevate your competitive edge with RJ Lee Group's industrial process expertise. Contact us today to embark on a journey of continuous improvement and success.