RJ Lee Group 7 min read

Alkali-Silica Reaction

Contributors

RJ Lee Group

Subscribe to our newsletter

What is Alkali-Silica Reaction?

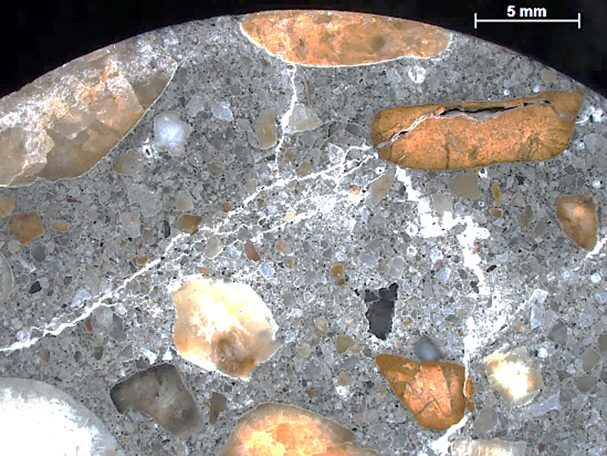

Alkali-silica reaction (ASR) is a common cause of premature concrete deterioration, resulting in expansion and cracking of concrete elements. ASR is a chemical reaction between alkali hydroxides in the pore solution of concrete and certain siliceous (silica-bearing) rocks and minerals present in some concrete aggregates. The result is the formation of a hydrophilic gel (aka ASR gel, or reaction product) that swells with a sufficient supply of moisture. The swelling pressure can lead to micro-cracking of the aggregate particles and surrounding cement paste (Fig 1), and bulk volumetric expansion and surface macro-cracking of the structure (Figs 2 and 3). Reactive forms of silica (SiO2) include microcrystalline or cryptocrystalline quartz, amorphous silica, and strained quartz. These can be found as chalcedony, cristobalite, opal, and volcanic glass in various rock types. Notable deleteriously reactive rock types include cherts, rhyolites, tuffs, and siliceous carbonates (limestone and dolostones)1.

Cracking as a result of ASR facilitates the ingress of water into the concrete. This water may carry aggressive chemicals such as chlorides that can cause corrosion of the reinforcing steel. Water ingress can also result in freezing and thawing damage despite adequate air entrainment2-3. In addition, ASR can cause severe reductions in tensile strength and stiffness, and modest reductions in compressive strength of the concrete4-5. These combined effects can lead to significant reductions in the service life of ASR-affected structures.

Diagnosing Alkali-Silica Reaction

Diagnosis of ASR typically begins with visual inspection prompted by the presence of characteristic surface features, such as macro-cracking, gel exudation and staining along the cracks, closing of expansion joints, and even localized crushing (blowups) in pavements. Cracking in reinforced concrete is typically aligned preferentially with the primary reinforcement (Fig 2), while in unrestrained plain concrete the cracking is more random and commonly referred to as map cracking (Fig 3). Many of these visual features can also be caused by other deterioration mechanisms such as drying shrinkage, freezing-and-thawing, and delayed ettringite formation (DEF), or a combination of mechanisms that may include ASR. Therefore, visual inspection in the field must be supplemented by laboratory analyses, including concrete petrography, to determine the cause(s) of the concrete deterioration.

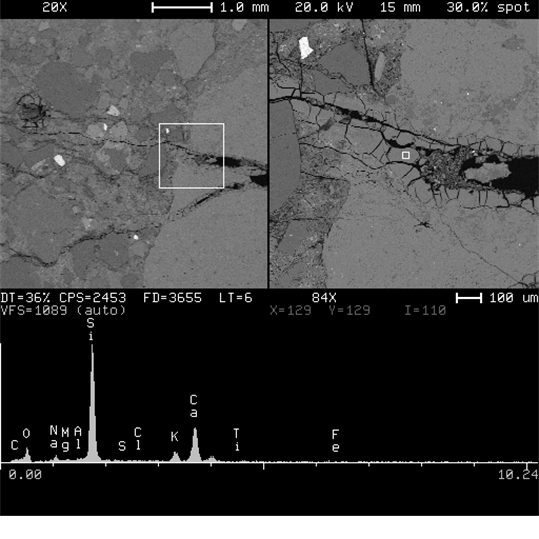

Petrographic examination of concrete core samples (ASTM C856) and Scanning Electron Microscopy (SEM) analysis (ASTM C1723) can be used to identify the presence and extent of ASR. SEM analysis is particularly useful in positively identifying the presence of ASR gel. The gel has a characteristic texture resembling cracked, dried mud (Fig 4). The reaction starts within a cracked aggregate and propagates into the cement paste. Energy dispersive x-ray spectroscopy (EDS) is combined with SEM analysis (SEM-EDS) to determine the elemental composition of ASR gel, which is primarily silicon, with lesser amounts of calcium and traces of potassium and sodium (Fig 4). Fresh, or recently formed, gel is relatively high in silicon, potassium, and sodium. Over time, calcium ions from the pore solution will replace sodium and potassium in the gel, and the gel morphology changes. Characterizing ASR gel is important because the presence of fresh gel can be an indication that swelling and cracking will continue; aged, calcium-rich gels have less swelling potential and may indicate the reaction is complete. The result of these analyses can guide engineering decisions about the management of ASR-affected structures.

- C295 – “Standard Guide for Petrographic Examination of Aggregates for Concrete”

- C856 – “Standard Practice for Petrographic Examination of Hardened Concrete”

- C1723 – “Standard Guide for Examination of Hardened Concrete Using Scanning Electron Microscopy”

References

1 Thomas, M.D.A., Fournier, B., Folliard, K.J.; “Alkali-Aggregate Reactivity (AAR) Facts Book,” FHWA-HIF-13-019, March 2013.

2 Wood, J.G.M. “Comparison of Field Performance with Laboratory Testing: How Safe and Economic are Current AAR Specifications?” Proceedings of the 11th International Conference on Alkali-Aggregate Reaction in Concrete, Québec City, 2000, pp. 543-552.

3 Bérubé, M.-A.; Chouinard, D.; Pigeon, M.; Frenette, J.; Boisvert, L.; and Rivest, M., “Effectiveness of Sealers in Counteracting Alkali-Silica Reaction in Plain and Air-Entrained Laboratory Concretes Exposed to Wetting and Drying, Freezing and Thawing, and Salt Water,” Canadian Journal of Civil Engineering, V. 29, No. 2, 2002, pp. 289-300. doi: 10.1139/l02-011

4 ISE. Structural Effects of Alkali-Silica Reaction. London: The Institution of Structural Engineers, SETO, 1992, 45 pp.

5 Ahmed, T., E. Burley, S. Rigden, and A.I. Abu-Tair. “The Effect of Alkali Reactivity on the Mechanical Properties of Concrete,” Construction and Building Materials, V. 17, 2003, pp. 123-144.

6 Giannini, E.R.; Wood, S.G.; Sanders, J.H.; Gore, E.R.; Klaus, K.; Moser, R.D. “Revisiting an Historic Case Study: Monitoring and Assessment of ASR in a Decommissioned Lock Structure,” Proceedings of the 15th International Conference on Alkali- Aggregate Reactions in Concrete, São Paulo, Brazil, July 2016. 10 pp.

Applicable RJLG Services

Petrography of Aggregates

Concrete Petrography

Aggregate Reactivity Testing

Nondestructive Testing

SEM/EDS

CCSEM

ICP-MS

XRD

EBSD

ASR-Related RJLG Project Examples

Concrete railroad ties

Airfield pavements

Monitoring system for nuclear

power plant structures

Parking decks

Bridges

This summary description is offered for educational purposes only and no warranty (express or implied) is given on the applicability of this information to any particular part, material, application, or product. This article is not intended to be a complete dissertation on this topic and the reader is encouraged to contact RJ Lee Group for consultation regarding individual applications, materials, or situations.